Structure and properties of polyamide

Nylon is the general name for a family of synthetic polymers that was first produced in February 1935 by Wallace Carothers at Dupont. Because this polymer is produced by connecting repeating peptamide units (amide bonds), it was also called polyamide.

In addition to heat resistance, these materials also have high electrical resistance and, due to their crystalline structure, they show good chemical resistance. Another property mentioned for nylons is their impermeability; while the flame resistance of these materials can be easily increased by compounding. By adding glass fibers and increasing the strength of these materials, they can be used as suitable alternatives to metal parts.

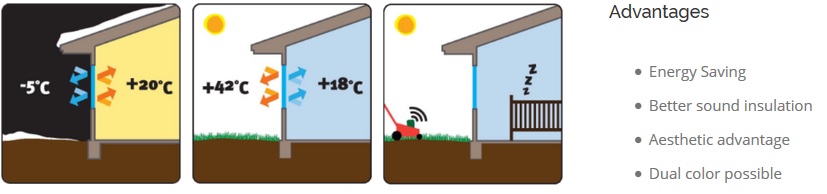

Due to the rapid molding of polyamide 66 and its other mechanical properties, including its center of symmetry and melting point, tensile strength, hardness, and high thermal and chemical resistance, its strengthened grade, combined with 25% by weight of glass fibers, is used to produce thermal insulation strips for sewing into thermal break aluminum profiles. These polyamide insulation profiles, due to their high physical and mechanical capabilities, insulate the aluminum profile from temperature changes in different seasons of the year while maintaining its strength.

Granules are a type of structure found in polymers. The structure of granules is in the form of grains that are used in the production of many plastic materials, including polyamide strips. In fact, granules are in the form of spherical grains that are shaped in different ways to produce different materials. In fact, the molecular type of granules can be any type of plastic, but the structure of granules refers only to a specific type that has a spherical shape. It is obvious that granules have different degrees or grades in terms of quality. If granular materials are produced directly from petrochemicals and referred to the manufacturer for the production of plastic materials, they are considered new granular materials, but if granular materials are produced from recycled raw materials, they become waste raw materials, and each plastic loses its granular properties after being recycled several times.